Gifting has never been easier

Perfect if you're short on time or are unable to deliver your gift yourself. Enter your message and select when to send it.

Thank you for taking the time to learn more about our new, specially marked cans.

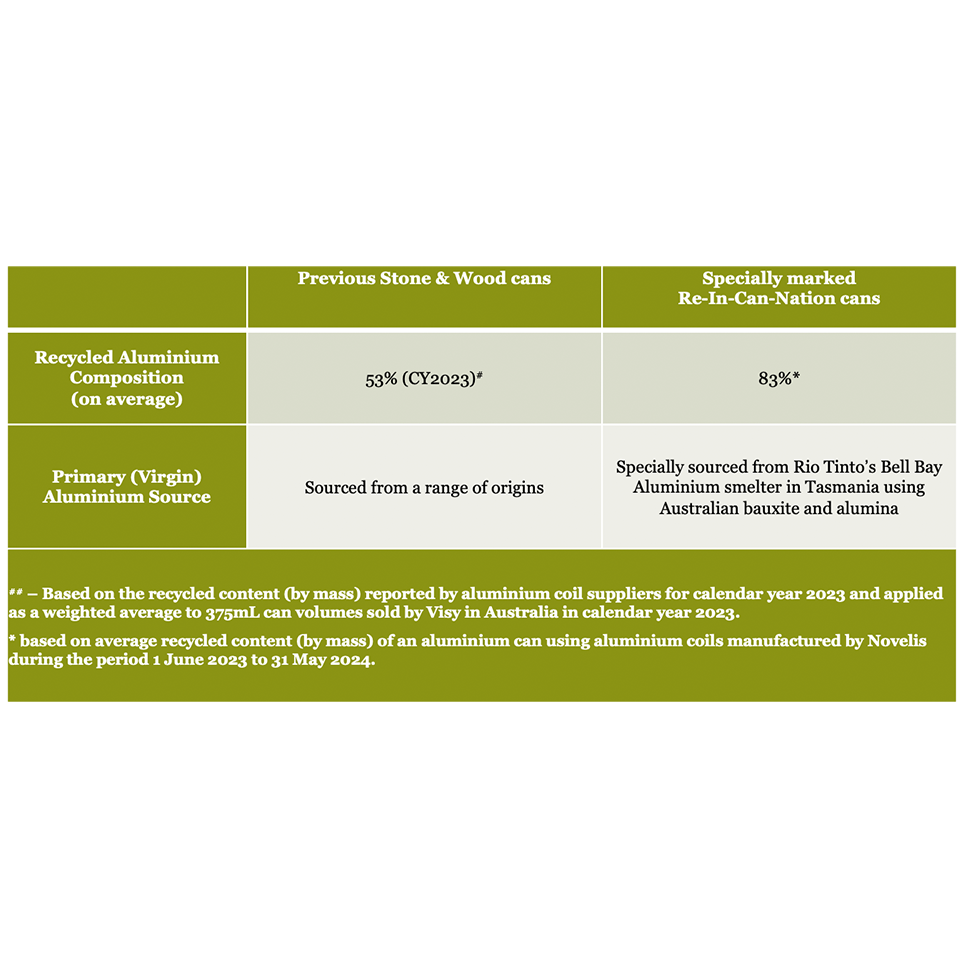

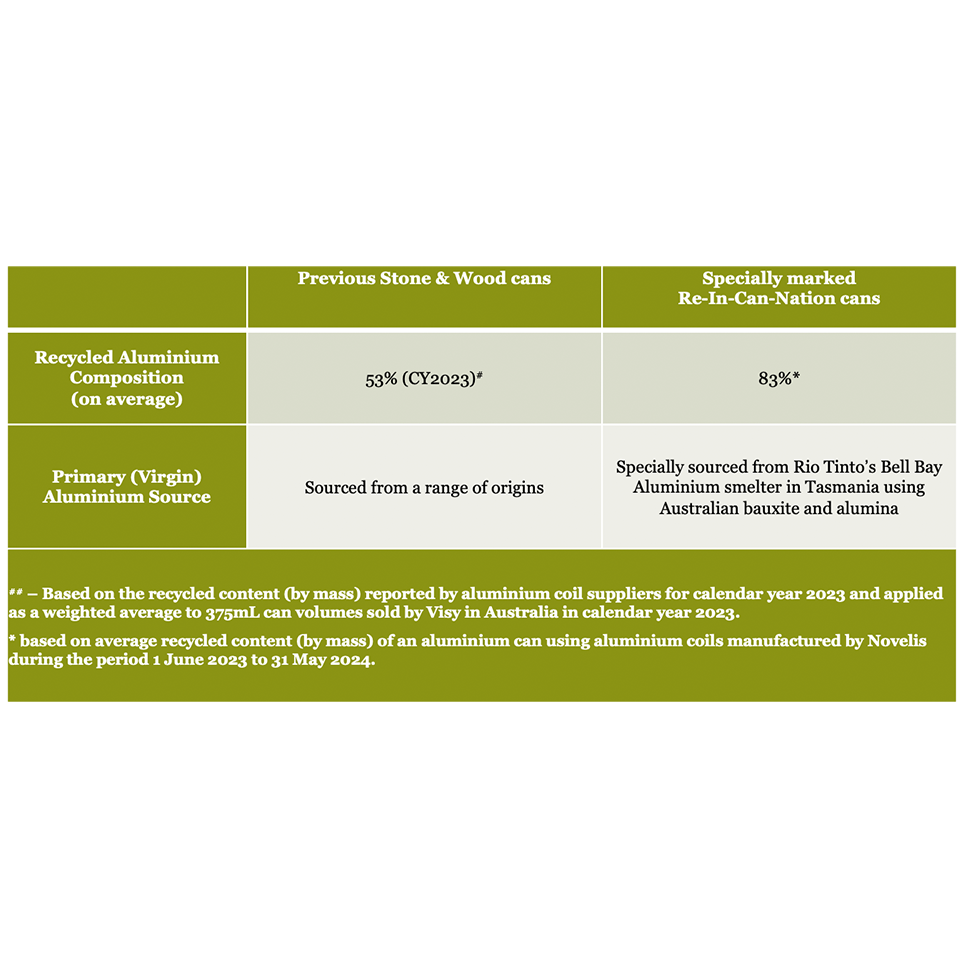

To highlight the importance of recycling, Stone & Wood has teamed up with our supply chain partners Visy, Novelis and Rio Tinto to trial a new can with a higher recycled aluminium content and lower carbon primary aluminium for packaging our products. Currently, only 64% of aluminium cans in Australia are being recycled**. We believe we can do better and that more cans in Australia should get a chance at a second life. To highlight the infinite recycling potential of aluminium cans, we decided to call our new specially marked tinnie - The Re-In-Can-Ation can.

Over the next 18 months, we expect to produce 15 million Re-In-Can-Ation cans, which is estimated to be the equivalent of reducing carbon emissions by 1,235 tonnes when compared to the equivalent quantity of our 2023 cans.^

Recycled content is the proportion (by weight) of recycled material in a product and was calculated on a mass balance approach (an average) over a 12-month period from 1 June 2023 to 31 May 2024.

Recycled material includes pre-consumer, as well as post-consumer recycled material (AS/ISO 14021: 2016).

‘Pre-consumer’ material is material diverted from the waste stream during manufacturing except reutilization of materials such as rework, regrind or scraps generated in the process and capable of being reclaimed within the same process that generated it.

‘Post-consumer’ material is material waste generated by households or by commercial, industrial and institutional facilities in their role as end-users of the product which can no longer be used for its intended purpose, including returns of material from the distribution chain.

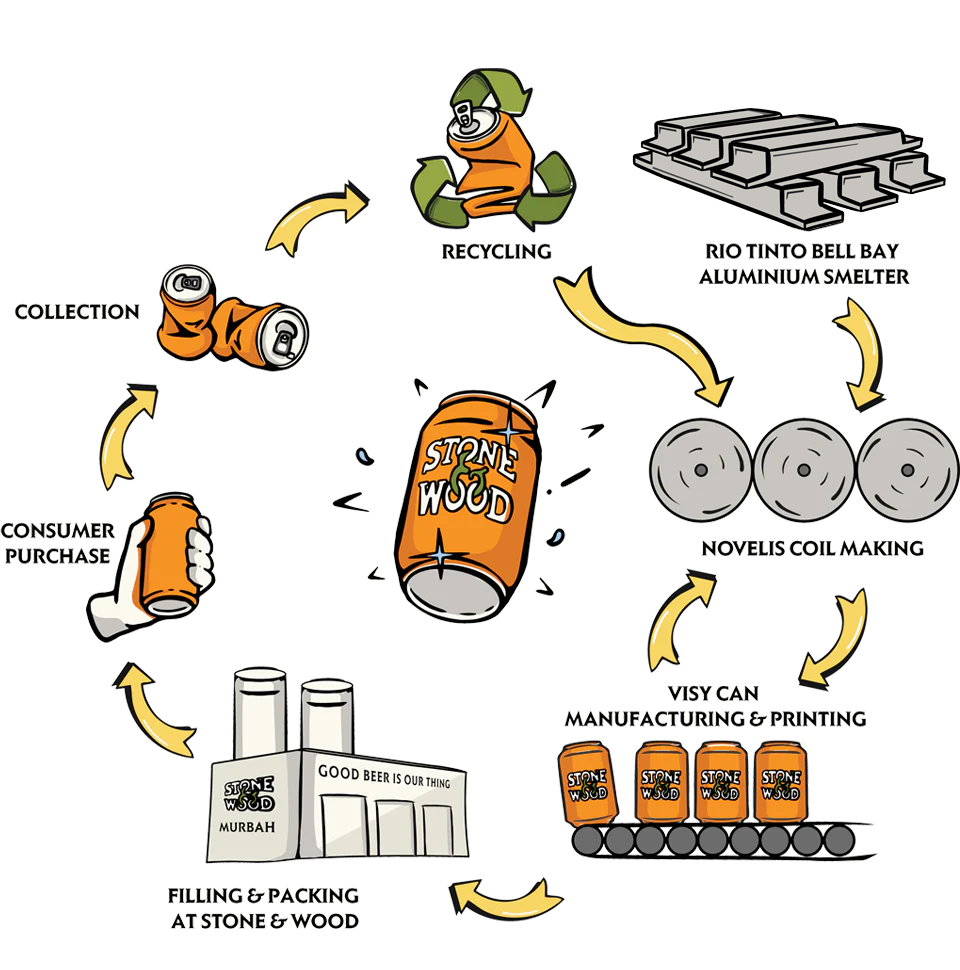

Our supply chain partners have contributed to this project in the following ways:

• Novelis manufactured the aluminium coils in South Korea with the increased proportion of recycled aluminium content. This included pre-and post-consumer recycled content. These aluminium coils also used a portion of primary (virgin) aluminium;

• Novelis worked with their supplier, Rio Tinto, to secure supply of low-carbon primary aluminium which was made at Rio Tinto’s Bell Bay Aluminium smelter in Tasmania; and

• Visy manufactured our cans locally at Visy’s site in Yatala, QLD, and then sent to our brewery for filling. Visy also supports the circular economy of aluminium by collecting and providing used beverage cans and scrap aluminium to Novelis for recycling.

Did you know only 64% of aluminium cans in Australia get a chance at a second life?

A significant amount of the carbon emissions involved in producing a can comes from the aluminium production, but the intensity varies depending on where the aluminium is sourced. There are two key ways to reduce the level of carbon emissions generated, we can either increase the amount of recycled aluminium that goes into a can or use primary aluminium with a lower carbon emission intensity. For this project Stone & Wood has worked with our partners to create a can that does both.

Primary aluminium starts with bauxite, the raw material in the ground, which is then

refined into alumina, and in turn sent for processing into aluminium. Due to these multiple processing steps, using recycled aluminium in a product often lowers carbon emissions compared to using primary

(virgin) aluminium. Our supply chain partners have worked hard to source as much recycled aluminium as possible, however, primary (virgin) material is still required.

The aluminium smelting process that turns alumina into aluminium, uses large amounts of electricity and is the most energy intensive part of the primary aluminium production process. To reduce the carbon emissions intensity of Re-In-Can-Ation cans, our suppliers have also sourced low carbon primary (virgin) aluminium made from Australian bauxite and alumina and produced at Rio Tinto’s Bell Bay Aluminium smelter in Tasmania.

What standard was used?

The Life Cycle Assessment (LCA) used for this calculation follows the ISO 14040/14044 (ISO, 2006b) Environmental Management Life Cycle Assessment standard.

What is and isn’t included in our calculations?

Our carbon emission calculations:

• use a “carbon dioxide equivalent” as a consistent measure of the effect of different greenhouse gases;

• apply to the “cradle-to-gate” stages of production for a standard 375mL beverage can.

• raw material extraction and processing

• upstream transportation

• manufacturing

• energy related emissions

• transportation to S&W

• the filling of the can

• transport to retailers

• use of product

• end of life of the can

• use cans produced by Visy during the 2023 financial year and corresponding data provided by their aluminium coil suppliers as its baseline; and

• for the Re-In-Can-Ation cans, use the most recent, third-party reviewed data from Rio Tinto, Novelis and Visy as at 1 July 2024.

Our carbon emissions calculations compare 375ml aluminium beverage cans with the following features (see table):

Collapsible content

At Stone & Wood, using business as a force for good is something that has been at the core of our philosophy from the beginning. Minimising our footprint and caring for our community is a focus for our business. We were the first Australian brewery to become B-Corp certified (learn more here), and our breweries are certified carbon neutral by Climate Active.

Beyond our commitment to reduce, reuse and recycle, we jump at opportunities to explore innovative practices that help improve the general life cycle of beer and industry standards. Packaging has always been a big contributor to the overall environmental impact of our product. Aluminium is highly recyclable and, in Australia, is easily collected through kerbside or container deposit schemes. However, when it comes to recycling rates there is huge room for improvement.

We believe our planet is the only one with beer on it and we need to work together to look after it. Please, make sure the can in your hand is being properly recycled to help us ensure a future with the highest possible level of recycled content cans.

A major factor in achieving high-levels of recycled content in cans is keeping cans in

rotation and out of landfill. Keeping cans in rotation, the circular economy,

and advocating for higher recycling rates must be a priority for governments, companies and each and every one of us. Together we can.

The recovery rate for aluminium beverage cans in Australia is 64%**. This means

for every 3 cans placed on the market, 1 is ending up in landfill or somewhere

it doesn’t belong. Our intention with this campaign is to have

a CAN-did conversation about how to improve the sustainability of our industry

and what each and every one of us can do to drive more sustainable outcomes.

** (Source: Australian Packaging Consumption &

Recovery Data 2022-23, Version 1 December 2024, Australian Packaging Covenant

Organisation (APCO). Available here.)

Cans are collected either through council-managed kerbside collection or can be dropped off at a return point under the Container Deposit Schemes (CDS) in each state.

From here cans are sorted and baled and can be processed into new cans. In order to achieve a higher level of recycled content in our cans, we need more cans to be kept in

the loop for them to be recycled. Individuals, government and companies have a huge opportunity to make a positive difference in this space.

We all have a responsibility, from consumer to government and producers. We need to raise awareness on the importance of the disposal of valuable resources in the right way to maximise their collection, recycling and reuse. The fact that only two thirds of our aluminium cans are currently recycled isn't good enough. We need governments and industry to educate the public and make it easier and more convenient for people to recycle. We hope projects like this are doing their part in raising awareness and making people excited to participate more.

Yes! Recycle more, spread the word and pick up litter where you see it. Participate in your local container deposit scheme and donate your refunds to local community groups, schools or charities to help them raise funds. Make submissions to your local council to provide greater access to recycling in public areas while also providing greater education and advocacy for correct disposal and recycling of materials. People should also demand greater access and education around recycling from their employers, local clubs and businesses.

Due to the small size of the Australian market, there are no facilities which manufacture rolled aluminium coil for beverage cans. Therefore, to turn used aluminium cans into new cans they need to go offshore for processing. Visy collects used beverage cans and other recyclable aluminium and sends it to our supplier of aluminium coil, Novelis in South Korea, where it is processed into new aluminium coil, ready for manufacturing beverage cans. Novelis, the world leader in aluminum rolling and recycling is one of the largest suppliers of aluminium coil to the Australian market and one of the largest purchasers of Australian used beverage cans for recycling back into aluminium cans. Even though used beverage cans are shipped overseas to be recycled, Visy and Novelis work closely together to drive circularity of the available cans.

Our B Corp Certification is one of the many ways that we hold ourselves to account. As a member of the B Corp movement, we have made a formal and legal commitment to consider the impact of our decisions on our stakeholders which includes employees, customers, suppliers, community, and the environment.

We were thrilled to be the first brewery in Australia certified as B Corp back in 2016, but achieving accreditation doesn’t mean we get to rest on our laurels, we are committed to continuing to improve. You can stay up to date with our B Impact score at bcorporation.net